Packaging Production Line

DHT Packaging’s Integrated Production Line: From Virgin Resin to Premium FIBC Solutions

At DHT Packaging, we take pride in our state-of-the-art, end-to-end production line. By maintaining a fully integrated manufacturing process, we ensure total control over quality, durability, and customization for every Jumbo bag that leaves our facilities.

1. High-Precision Extrusion & Spinning

The process begins with 100% virgin Polypropylene (PP) resin. Our advanced Extruder Lines transform these raw materials into high-tenacity tapes. During this stage, UV stabilizers are added to ensure the fabric can withstand long-term exposure to sunlight and harsh environments.

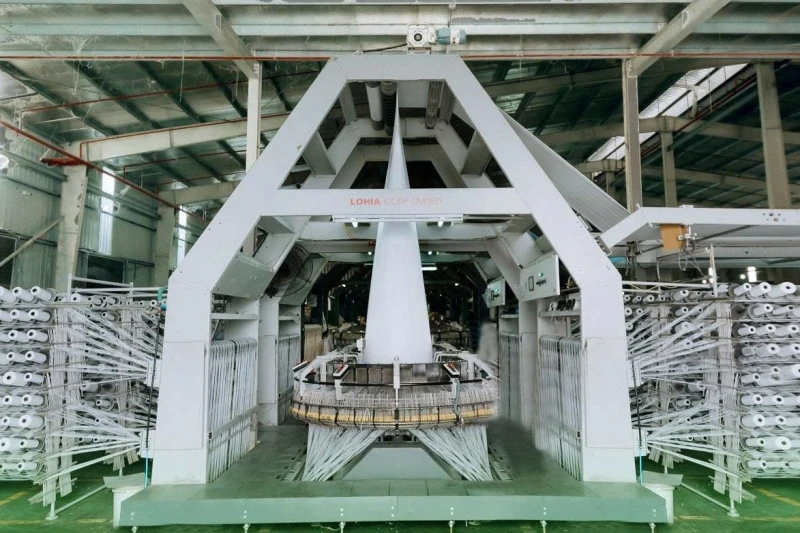

2. Modern Weaving Technology

Our Circular Weave Looms and Water Jet Looms weave the PP tapes into heavy-duty fabric. This stage is critical for determining the bag’s burst strength and breathability. We offer various fabric weights (GSM) to meet specific load requirements, ranging from 500kg to 2,500kg.

3. Automated Cutting & Professional Printing

Once the fabric is ready, our Automatic Cutting Machines ensure millimeter-perfect precision for every panel. Following this, our Flexographic Printing Line applies your brand logo and safety information with high-speed accuracy, using durable inks that remain vibrant throughout the shipping process.

4. Specialized Belt & Webbing Production

Simultaneously, our specialized webbing machines produce the Lifting Loops (Belts). These are the "muscles" of the bag, engineered with a Safety Factor (SF) of 5:1 or 6:1 to guarantee safe handling during crane operations.

5. Skilled Sewing & Final Assembly

In our expansive Sewing Room, over 250 skilled technicians use specialized heavy-duty sewing machines to assemble the bags. We use reinforced stitching and sift-proof seams (for fine powders) to ensure the highest structural integrity.

6. Rigorous Quality Control (QC)

Before packaging, every bag undergoes a final inspection. We use specialized Test Machines to verify load capacity and seam strength, ensuring that 100% of our products meet ISO 9001:2015 standards.

With a capacity of 2,000,000 bags per year, DHT Packaging’s production line is ready to scale with your business needs.

Other News

Line Cutting Machine, Printing Machine

Line Cutting Machine, Printing Machine

Read More →